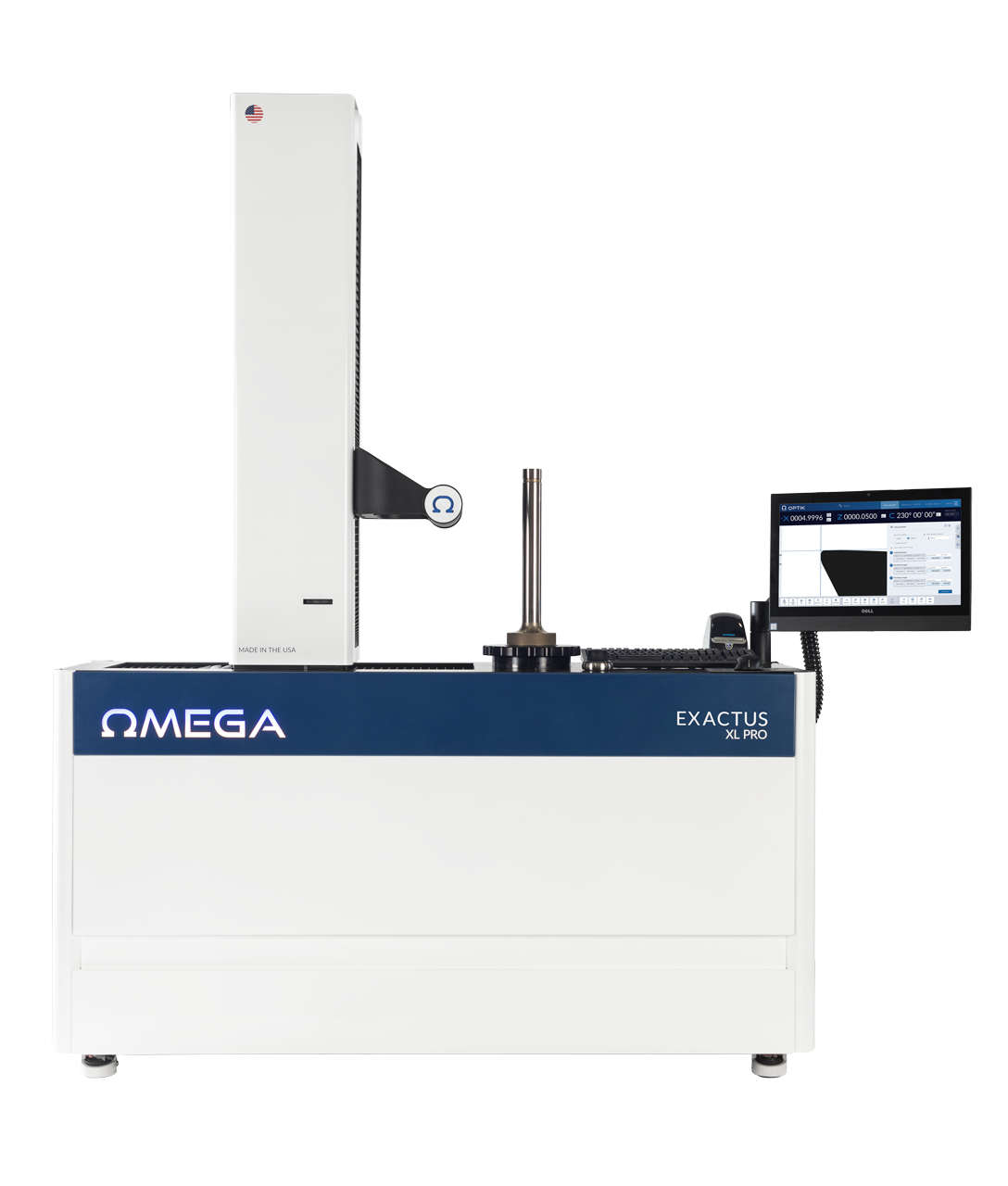

EXACTUS – XL

Cast iron construction with our proprietary SYMMETRY design, our innovative virtual control device, and multiple spindle options make the Exactus-XL the definition of the word “heavyweight”.

- Precision ground taper 50 spindle

- Integrated spindle brake and 360° indexing

- Simple to use 3D Virtual Control Device with programmable smart buttons

- Shop floor ready, full size freestanding machine

- Precision Tool Tip Finder

- Cold Source LED Tool Inspection Light

- Robust easy to use control interface

- Pearlitic cast iron construction with our proprietary SYMMETRY design

- Instantly finds tool geometries

- Theoretical intersection points

- Fixed or Dynamic cross-hairs

- OPTIK Tool Measuring and Management Software Suite

- 21.5” touch-screen monitor

- 70x Magnification lens

- Casters

DIMENSIONS AND WEIGHT

- Overall Width: 1838mm (72.4”)

- Depth: 701mm (27.6”)

- Height:

- 600mm Column (1948 mm/76.7”)

- 1000mm Column (2342mm/93.2”)

- Average Shipping Weight: 1020kg (2240lbs.)

MEASURING LENGTHS

- 650mm – 1000mm Length

- 600mm Maximum Diameter

UTILITIES

- 120V AC or 220V AC, 50Hz to 63Hz

- Air: 80-110PSI

CONTROL SYSTEM OPTIONS

- Manual and automated RFID systems

- Mazak Cyber Tool and Smooth Tool Management system integration

- Data output

- Perfect Set, AAIM, and ECHO software modules

- Taper 60 spindle

- HSK 125a spindle

- User management

OPTIONS

- Autofocus CNC Spindle

- Dual 21.5” monitors for tool management window and OPTIK software

- Label printer

UPGRADE TO EXACTUS XL PRO

- System is full 3 axis CNC automation

Compare Presetter Lineup Features

PRO Capability Available

Any machine with PRO capabilities has full 3 axis CNC automation.