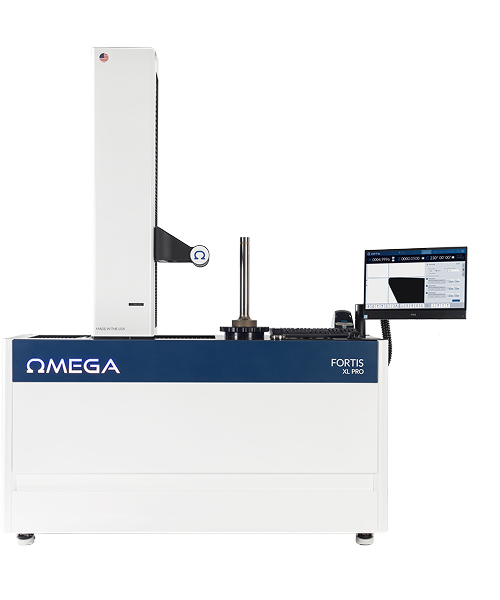

Wings of Precision: Meet the FORTIS Series – The Ultimate Presetter for Large Tools

Built for Power. Made to Adapt. Engineered to Last.

In modern manufacturing, precision is essential, and efficiency is just as critical. The FORTIS Series of tool presetters for large tools from Omega TMM delivers both.

Developed to handle a wide range of tooling sizes, machine environments, and operator skill levels, the FORTIS Series includes FORTIS, FORTIS PRO, FORTIS XL, and FORTIS XL PRO. Each model offers increasing levels of automation, capacity, and control, giving you the flexibility to match the right machine to your specific shop needs.

But before diving into specs and model comparisons, let’s step back and answer a foundational question.

What Is a Presetter, and Why Does It Matter?

A tool presetter is a machine that accurately measures cutting tools outside of the CNC machine. Rather than spending valuable cycle time touching off tools at the spindle, a presetter allows you to:

- Measure tool length and diameter quickly and accurately

- Detect wear or damage before loading tools into the machine

- Set up jobs offline to keep spindles running

- Transfer data seamlessly into your control or tool management system

- Avoid human error and reduce scrap caused by bad offsets

For machine shops looking to reduce downtime, extend tool life, and improve first-piece accuracy, a presetter is one of the highest ROI available.

The FORTIS Series takes this concept and scales it. It gives you the tools to measure confidently, whether you’re working with standard holders or oversized, heavy-duty tooling in high-horsepower environments.

Meet the FORTIS Series: Four Models. One Platform. Limitless Possibilities.

Each model in the FORTIS lineup shares a common foundation:

- 500+ lbs spindle clamping force with a mechanical locking system and interchangeable cartridge system for maximum taper compatibility (CAT, BT, HSK, Capto, and more)

- Symmetry cast-iron construction for thermal stability

- Made in Fairport, NY, with full support from Omega TMM’s domestic engineering and service teams

Let’s look at how the models compare and where they fit in:

FORTIS

Manual operation, maximum value.

The base model in the series, FORTIS is a manually controlled presetter perfect for job shops, toolrooms, and small to medium production environments with tighter tolerances. Its high-precision spindle and robust database allow for fast, repeatable measurements with minimal operator training. Built for rugged reliability and precision, it’s a foundational tool for any shop stepping into offline presetting.

Ideal for: General machining, toolroom support, mold shops, job shops

Benefits: Fast tool prep, avoids spindle time waste, affordable entry point

FORTIS PRO

CNC automation for high-volume repeatability.

Upgraded with 3-axis CNC automation and powered by Omega’s OPTIK software suite, the FORTIS PRO brings hands-free measuring and advanced routines into the mix. Operators can run preprogrammed macros, minimize human error, and maximize consistency across shifts.

Ideal for: Aerospace, automotive, medical, production environments

Benefits: Automation reduces labor time, ensures consistency, integrates into digital workflows

FORTIS XL

Built to handle your biggest tools.

Designed with heavy-duty machining in mind, the FORTIS XL accommodates tools up to 1000mm in length and over 1000 lbs in weight. Its extended Z-axis travel and reinforced design make it the go-to solution for large-format cutting tools that traditional presetters cannot manage.

Ideal for: Oil and gas, shipbuilding, heavy equipment, large-part manufacturing

Benefits: Eliminates manual tool touch-off for oversized holders, improves safety, and reduces setup strain

FORTIS XL PRO

The best of both worlds: size and automation.

Combining the capacity of the XL with the full CNC automation of the PRO, the FORTIS XL PRO is built for the most demanding applications. This is a production powerhouse, ready for shops running tight tolerances on oversized tools, shift after shift. There is also a special Tribos option for this machine that accommodates Schunk Tribos tooling.

Ideal for: Aerospace engine components, defense, complex parts requiring frequent tool changes

Benefits: Automates heavy tool measuring, reduces operator fatigue, supports flexible manufacturing workflows

Where Does FORTIS Fit in Your Shop Workflow?

The FORTIS Series excels in any environment where tool changeovers need to be quick, accurate, and reliable. Some of the key workflow improvements include:

- Keeping spindles cutting while tools are being measured offline

- Reducing crashes and scrap from manual entry mistakes

- Improving tool management and inventory visibility

- Helping shops cross-train staff more easily with user-friendly interfaces

- Supporting flexible manufacturing with quick cartridge swaps across taper types

Whether you’re running one CNC machine or an entire cell, the FORTIS Series adapts to your scale and scales with your growth.

FORTIS + FORTIS PRO Spec Sheet FORTIS XL + FORTIS XL PRO Spec Sheet

Made in the USA. Backed by 77+ Years of Manufacturing Expertise.

Like all Omega TMM machines, the FORTIS lineup is designed, machined, assembled, and supported in Fairport, New York. That means:

- No international delays

- No tariffs

- Real service from real people who understand your shop floor

It also means you can see the machines in action – visit us in person or schedule a live virtual demo from our Customer Center.